March 19,2024

- Next generation fiber technology based on Polyacrylonitrile (PAN) acrylic obtained from the reaction of acrylonitrile monomers.

- –Precursor to Carbon fiber.

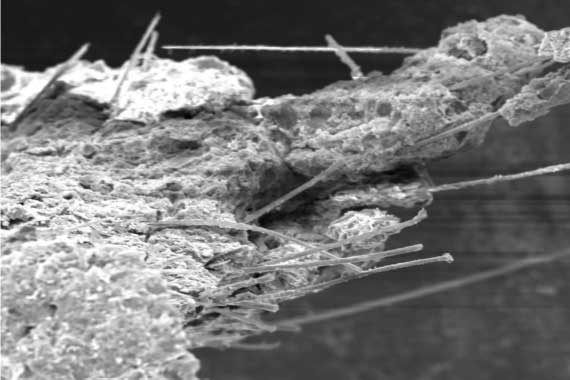

- Proven to significantly increase the mechanical properties through ionic & chemical bonding with cement and to effectively seal formation fractures improving top of cement, lost circulation control, and fluid loss.

Fiber Characteristics

- Material – PAN Acrylic Fiber

- Fiber Length – 1.8mm, 3mm and 6 mm

- Milled (0.5-1.5mm) also available in higher denier.

- Acid & Alkali Resistance – Excellent

- Specific Gravity – 1.17 g/m3

- Decomposition Temperature – 330oC/626oF

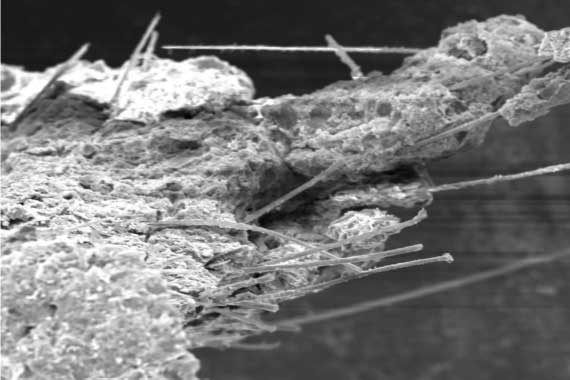

- Diameter <11 microns (1.0 denier)

- Very Large Surface Area to Volume Ratio

- Tenacity >600 MPa

- Fiber Color – Natural

RadiLock Fibers Benefits

- Used in areas where lost circulation control is critical, while also providing a more durable, long-lasting cement.

- The only multifunctional fiber technology in the market today:

- –Return to surface properties are enhanced

- –Pumping with cement due to multiple the benefits including the benefit of mechanical properties, fluid loss, improved bonding

- Fiber technology that can be dosed in the bulk plant for consistent loadings, while also being hand dosed at site in cement & spacers.

To lean more about Riteks RadiLock Fiber Technology’s fiber count, additional benefits, and conducted tests:

DOWNLOAD FULL RITEKS RADILOCK FIBER TECHNOLOGY DOCUMENT »