Oilfield asset management is never truly complete until the well is capped for good. When it comes to healing cement fractures, the industry standard is to apply a “band-aid.” While applying a substance like fiberglass or polypropylene on top of a fracture can hide the damage, it doesn’t repair the break, nor does it prevent more cracks from developing.

That’s where our RadiLock Fiber comes in, setting a new standard in cementing solutions, as it heals a fracture from the inside out, improving cement bonding at both the ionic and chemical levels.

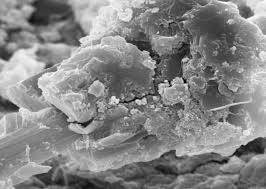

RadiLock is a highly advanced, next-generation fiber technology based on polyacrylonitrile acrylic taken from the reaction of acrylonitrile monomers. When RadiLock is applied to a cement fracture, it penetrates and clogs the hole and/or loss zone with a large number of fibers. To be exact, RadiLock consists of 1,360,791,073 fibers per every pound of product, which means it possesses a much higher fiber density than other competing products.

This high fiber count per pound means your cement formations will stay strong and stable throughout the duration of your project. RadiLock is the only multi-functional fiber technology in the market today, preventing leak-off, fluid loss, and fallback in construction projects.

Not only does this product offer service companies a highly effective “cost-in-use” solution to act as their primary loss circulation additive, RadiLock also helps create a more robust, durable cement thanks to its mechanical property improvements. While similar products do not bond to cement, RadiLock is actually a strong cement-bonding agent that’s proven to significantly improve the integrity of cement structures through ionic and chemical bonding. Instead of acting as a “band-aid” to cracks in cement, it heals the damage and creates a tough bond that will stay intact–even under the harshest conditions around the world.

RadiLock effectively seals formation fractures from the inside-out, repairs the top of cement, and prevents fluid loss. Unlike our competitor’s products, it can be dosed in-bulk at the plant for consistent loadings hand-dosed on-site in cement and spacer mixes. This versatility means Radilock is a perfect fit for a wide variety of oil and gas projects.

RadiLock maintains thermal stability of up to 600 degrees Fahrenheit, while other similar products have a thermal degradation temperature of 250 degrees Fahrenheit or lower. This temperature stability means it can withstand the toughest environments, and RadiLock will stay strong even in extreme temperatures. Additionally, this product possesses excellent acid and alkali resistance.

Through a combination of the ideal fiber count, specific gravity, thermal stability, and incredible bonding strength, RadiLock helps to improve the strength and durability of cement formations.

If you’d like to assess if RadiLock is right for your cementing solutions toolkit, contact Riteks today. Our top priority is making sure we pair you with the right product solutions for your individual oilfield business needs. Our technical team stands ready to assist and provides quick turns on every order via ready inventory warehoused in strategic locations. Let our decades of oilfield servicing experience work for you.